N.S.PRO MODUS3 HYBRID

MODUS3 hybrid shafts born from patented technology.

Integrating the best of steel and graphite required inimitable technology in both types of shafts.

Hybrids and/or driving irons are increasingly used for precise tee shots requiring distance control and for second shots on longer-distance holes.

But steel and graphite shafts both have their advantages and disadvantages – neither is superior overall.

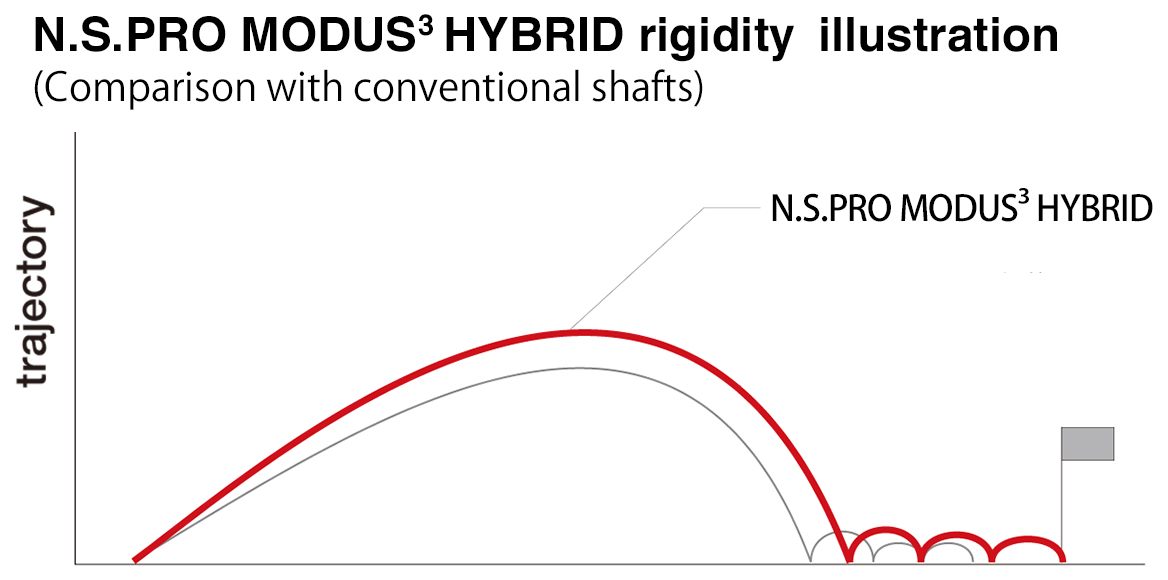

As a shaft maker with extensive knowledge of both steel and graphite, Nippon Shaft developed a new hybrid shaft that delivers both higher trajectory and tighter dispersion with pinpoint accuracy.

The key to our success was our patented adhesive technology that allows us to take full advantage of graphite’s design flexibility to ideally integrate steel and graphite.

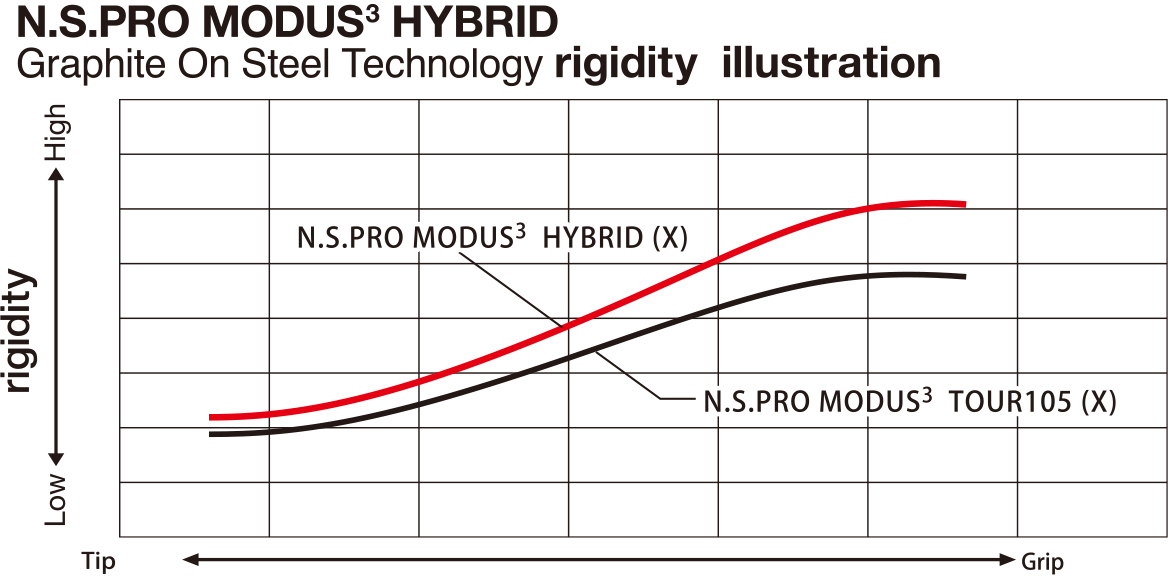

Not only does this composite design compensate for the lack of rigidity in steel, but it combines the solid feel and spin control of steel with the flex control of graphite. In essence, N.S.PRO MODUS3 HYBRID Graphite On Steel Technology results in an ideal hybrid shaft with many of the advantages and none of the disadvantages of steel and graphite.

A patented composite structure runs the entire length of the shaft to combine the easy launch and high trajectory of graphite with the solid feel and tight dispersion of steel.

A patented composite structure runs the entire length of the shaft

To deliver the carry distance and elasticity of graphite, as well as the contact feel and spin control of steel, we securely combined an ultralight steel shaft and graphite layer using patented advances in manufacturing and adhesive technology.

The unprecedented shaft characteristics of N.S.PRO MODUS3 HYBRID Graphite On Steel Technology open up exciting new possibilities for competitive players to maximize hybrid and driving irons performance.

The advantages of steel and graphite – without the drawbacks

Our patented technology ideally combines steel and graphite.

The steel delivers carry distance as well as directional stability due to its inherent resistance to twisting.

The graphite, in multiple thin layers, balances weight and hardness while maintaining a solid feel.

Spin control is enhanced by the overall thin structure, optimizing the restorative force. Moreover, a strong rebound force enhances the feeling of solid impact.

Whether using a hybrid or driving iron, MODUS3 Hybrid is now the best solution in terms of both feeling and function.

| PRODUCT | FLEX | LENGTH INCH (IRON #) |

WEIGHT (G) |

BALANCE POINT (%) |

TORQUE (°) |

KICK POINT |

SHAFT DIAMETER (IN) |

|

|---|---|---|---|---|---|---|---|---|

| Butt | Tip | |||||||

| N.S.PRO MODUS3HYBRID Graphite On Steel Technology |

HL | 41(1046) | 91.0 | 52.2 | 2.6 | Grip | 0.596 | 0.370 |

| S | 41(1046) | 91.0 | 52.2 | 2.8 | Grip | 0.596 | 0.370 | |

| TOUR S | 41(1046) | 91.0 | 52.2 | 2.8 | Grip | 0.596 | 0.370 | |

| X | 41(1046) | 101.0 | 52.2 | 2.5 | Grip | 0.596 | 0.370 | |

| TOUR X | 41(1046) | 112.0 | 52.2 | 2.3 | Grip | 0.596 | 0.370 | |

※ .355(9.02mm) Taper tip is also available

N.S.PRO MODUS3

FAQ

-

What are the features of steel shafts and graphite shafts?

-

I’m interested in reshafting. But I have no idea which shaft to choose. Please give me advice.